Projects: Just a short blog, to show some progress.

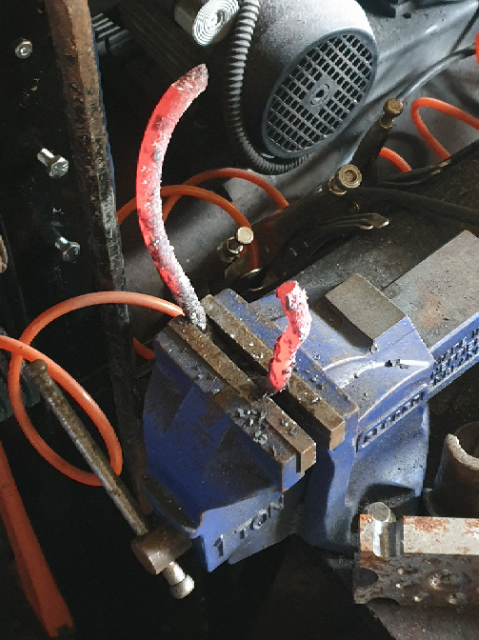

| Punched and drifted some steel, as I needed a chuck key for the lathe, not sure where my old one went. But ten minutes at the forge sorted it. |

|

||

|

Ford 3000 (force) from 1972. This

will be my workhorse in retirement. Note:

Pre-force (6X) models where made from

1965 until March 1968.

The pre-force were problematic and the

select O matic also had problems.

Force models (6Y) where made from April

1968 until 1975.

I have managed to accumulate a lot of literature on the 000 series, the original factory repair manual and parts catalogue, amongst many. |

||

|

A multi function trestle, which will be used near the forge. I am in the middle of another trestle build. | ||

|

Made from 10mm angle which was acquired from work. The hinges came from a skip and the arch was also from a skip. | ||

|

I needed a table, strong enough to take a

lot of weight. The top is 15mm steel plate 750mm x 500mm.

The legs are made from 8mm flat bar, welded as T bar. I created space

underneath to hold three tote boxes for offcuts. This table has

worked well, it holds a number 6 Denbigh flypress, small Record vice,

pipe vice and I also made a holder to hold a creasing iron. The

20kg Becma anvil sits on a Cedar log, with a strap around the front

table leg. Underneath, I now store reels of mig wire and arc rods, which I store in sealed tubes.

The press has since been painted black. |

||

|

I have a habit of picking up metal for free. In this case, I picked up several pairs of forklift tines. It's not bad as a medium tool steel. | ||

|

A Brush PTO genny, about 10 kva. It came from an old dairy farm, only used as a backup. I was told that it was little used. It is three phase, I have also acquired a single phase splitter cable. | ||

| Ifor Williams 142 tri axle, I couldn't have done half of the work without this. I have owned a few trailers, but nothing tows like this. I think it dates from 2008. |

|

||

|

I am not the best welder in the world, but I am happy with this. Not all my welds are this clean. This is 10mm flat bar using around 100 amps. | ||

|

A small John Deere 212. I plan to make a trailer, to make light work of moving things around. | ||

|

Denford Senior S type, for later projects. | ||

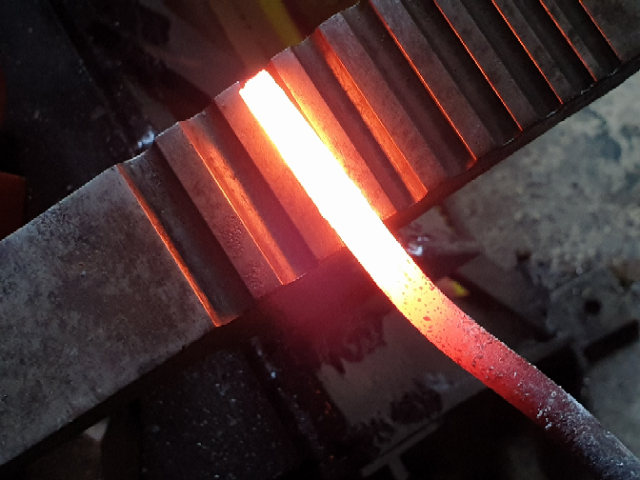

| The process of reforging a coil spring, I found this lying in the road, road conditions must be causing a lot of damage to cars. The final process is smoothing the metal, on the creasing iron. |

|

||

|

The Alfa Challenge 70. A handcrank sewing machine capable of sewing leather. |

||

|

The miniature Veritas, bevel up plane. I bought this, thinking it would not be useable. I was wrong, it is very handy for smoothing knife scales, before sanding. | ||